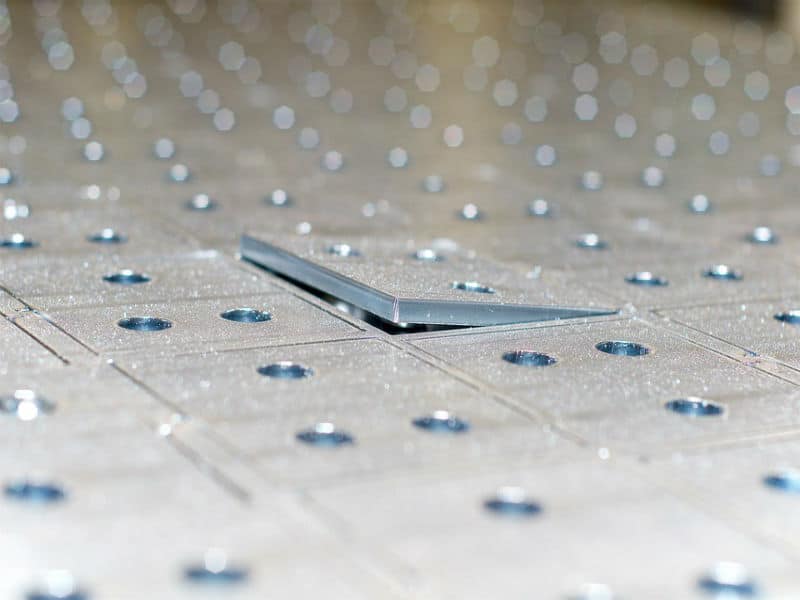

Sheet metal forming is an industrial process in which forces are applied to a piece of sheet metal to modify its geometry without removing any material. It is used in all the sectors of industrial production viz. automotive, aircraft, home appliance, food industry etc.

Due to its manufacturing process being extremely flexible allowing clients to get a variety of shapes to suit their needs, sheet metal forming is very popular in industrial sectors.

Advantages of Sheet Metal Forming

Efficiency and Accuracy

Using the latest CAD/CAM, CNC technology, and manufacturing equipment, the process of sheet metal forming is efficient and accurate.

Many companies employ CNC punch press machines which are programmed for the movement and positioning of metal sheets quickly along with punching the holes within a 0.05mm tolerance.

Metal sheets can also be formed using CNC hydraulic and electronic presses.

This process is suitable for repeat batch work.

Durability

Sheet Metals are strong, can tolerate high pressures and are malleable.

They can be transformed into any shape i.e. they are suitable for innovative architects and designers to work.

The finishing of sheet metal is done to create a durable surface which makes sheet metal resistant to sun, corrosion and moisture. Thus making sheet metal forming suitable for projects that involve products that need to be exposed to various weathers and climates.

Easy Repairable

Sheet metals can be easily inspected, and any damage can be found easily.

Damage can usually be easily repaired in a straightforward way.

You have to remove the damaged metal sheet from the structure, repair it and then replace it without dismantling the whole structure.

Low Cost

Offers an affordable and high-quality route for its customers to obtain a product they want to work with.

Benefits for Roofing Projects

The following are the advantages of sheet metal forming for roofing projects:

Long-Lasting Metal Roofs

Metal roofs are long-lasting compared to their asphalt counterparts.

Many metal roofs last at least twice as long as asphalt roofs. Some metal roofs may last for a hundred years.

Metal Roofs are Safe

One of the advantages of metal roofs is they are fireproof. Thus, they are safe. However, many people are concerned about the lightning effects on metal roofs.

They assume that metal roofs are vulnerable to the electric storm, but this is not the case.

Many buildings having metal roofs are not tall enough to catch electric shock. Also, such buildings are earthed.

Environmental Friendly

50% of the steel contained in a metal roof is recycled content.

Also, metal roofs can be recycled as well so they are environmentally friendly.

About J&J Engineering

J & J Engineering (Walsall) Ltd, have over 40 Years of Experience With Tube Bending, Manufacturing Metal Pressings, Fabrication & Welding. We pride ourselves on offering a prompt, personal and flexible service at competitive prices!

We manufacture high-quality metal presswork, welded assembly components and products including bespoke shelving and roof safety barriers/systems for clients in Birmingham, Walsall, other places in the West Midlands and throughout the UK. Established in 1978 we have worked with companies to provide a wide range of metal pressing and welded assembly components and products.

For more information regarding this, Give us a call: 01922710204 (or) Leave an email: sales@j-jengwalsall-ltd.co.uk